No products

Prices do not include tax.

Temperature control in hospitals: hospital thermometers

We recommend keeping medical equipment, drugs, vaccines, tissues and blood at the specific temperature appropriate for each case. As you know, the ideal temperature to avoid cell multiplication ranges from 20 to 25 °C. This is the usual temperature in corridors and common areas. However, different temperatures may be required in other areas, such as operating theatres or patients’ rooms.

Types of Hospitals

- Incubators

Temperature and humidity control for incubators

Temperature control in neonates is essential for their development, especially in the first week. This is one of the critical factors, as well as humidity, heart rate and baby weight. Premature babies lose body heat easily, due to, among other things, thinner skin. Continuous monitoring of body temperature as well as incubator air temperature is therefore necessary. For this, it is usual to apply a sensor to the lower abdomen, which continuously informs us of body temperature. Incubators are also equipped with an air sensor that regulates the temperature of the environment inside the cabin. Depending on the body temperature, the ambient temperature is adjusted, thus regulating the baby's temperature and making it remain stable at 36ºC.Temperature labels for incubators

The importance of temperature control in hatcheries for hatchlings, as well as other parameters, makes them fully equipped with electronic sensors. However, the use of temperature labels is very useful, as a redundant and at the same time comfortable system for visual control quickly. The temperature labels allow anyone to see the current temperature in an easy way and also guarantee that the sensors are working correctly. The adhesive thermometers, just stick them on the outside of the incubator and they will inform us at all times of the temperature inside. Likewise, when the baby is more advanced and leaves the incubator, there are fever thermometers, which allow them to stick to the skin and monitor the temperature comfortably in the first months. These thermometers through a color change, clearly indicate body temperature.Other incubators and temperature control

In addition to hatcheries for neonates, there are other types of incubators, oriented to animals or to the reproduction of chickens. The use of thermal labels in these incubators, facilitates the control task and complements the electronic type sensors of the same. Let's see some example in more detail:

Temperature control for chicken incubator

The temperature inside a chicken incubator should be around 38 °C to obtain high‑quality animals. However, you should be aware that this temperature value may vary throughout the incubation process. Therefore, a fully functioning incubator temperature sensor is required.

The reason behind this is none other than the mortality rate in chickens, if we keep a constant temperature and make the following mistakes:- Lack of maintenance on the incubator fan

- An increase in the number of eggs to be incubated

- Not drying the water that usually appears at the bottom of the incubator

- Problems opening the hatches

The importance of the incubator temperature sensor

This accessory is essential to make control and monitoring tasks easier. It will help you to detect if the temperature is too high, if there are any sudden variations, and check the temperature of the water that provides humidity.

Maintenance on the sensor is important so that we can correct whatever is necessary, at a glance. After the first 10 days, we advise you to regularly check the temperature of each egg’s shell to anticipate any problems.

The best thing to do is to adjust the temperature as the days go by, gradually lowering it from 38 to 35 °C. This scientifically proven method will allow you to raise chickens that develop their internal organs correctly and without defects.By using reversible thermometers, we can check if the temperature is right at any time. On the other hand, irreversible thermometers such as the 8‑level thermometer allow us to certify the maximum temperature reached and ensure that the process has been correct.

We hope we have managed to provide you with the fundamental notions to incubate your chicks correctly and without any worries. Having quality sensors and controlling the incubator temperature will make it much easier for you.

Hospitals Best seller

Adhesive reversible thermometer for refrigerators. This indicator comes with 12 temperature points indicating the temperature of the refrigerator or cold storage by a colour change.

LCD fridge thermometer with 12 levels...30,69 €This product is supplied in packets with 10 thermometers. Irreversible-type temperature indicator with 8 temperature points. This is an adhesive thermometer than can be stuck on any surface or product. The points are marked with temperature in ºC and ºF.

8-level irreversible thermometers (pack 10...15,93 €Tempsafe is an adhesive label changing colour by any temperature increase and displaying a message to alert on hot surfaces and avoid burns.

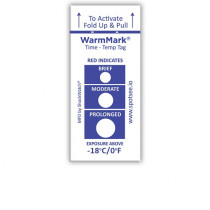

Tempsafe safety temperature indicator...32,49 €Irreversible time and temperature indicator by color change. This adhesive label alerts you to inappropriate temperature exposure by progressively changing the color of the control points. Each point is calibrated for a specific period of time, thus allowing control of the exposure time at that temperature.

WarmMark Time and Temperature (pack 100...238,00 €The FREEZESAFE temperature drop indicator is an adhesive label that, by means of a color change, alerts us that the temperature has dropped below a critical value. The color change is permanent and irreversible, so it acts as a control indicator, recording the event. It is supplied in packs of 100 units.

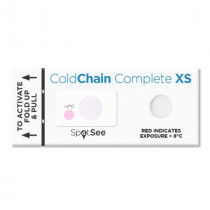

FREEZESAFE temperature drop indicator...193,00 €Coldchain complete XS is a temperature label for cold chain control. This indicator is irreversible and alerts us by means of a color change if a product has been exposed outside the required temperature range, both above and below it. It is supplied in packs of 100 units.

Coldchain Complete XS cold chain...322,00 €

Hospital air conditioning: main temperature control areas

The areas where you will need most control of the temperature are the pharmacy, especially its freezers and refrigerators; the equipment in which tissues and blood are transported and stored; the freezers where samples are stored; the clean rooms, cold rooms and laboratories; the operating theatres and, lastly, the testing rooms.

Hospital autoclave, a device with specific requirements

Areas where sterilization processes are carried using devices such as the hospital autoclave and other medical equipment, both diagnostic and therapeutic, also require a specific temperature.Temperature control in hospitals

Our approach to hospital air conditioning and temperature control involves the installation of visible thermometers. Supervisors or managers need to view and monitor the temperature easily. To do so, we will use reversible LCD thermometers that are visible and easy to use. Just stick them within the area to be controlled. They will clearly display the temperature by changing colour.

There are special areas, such as the operating theatre, where the temperature will fluctuate in a range between 18 and 22 °C. Therefore, the entire temperature control system will be vital in providing a suitable environment and atmosphere. In these environments, integrated circuit systems are the most appropriate. Using adhesive thermometers, which are an affordable solution, is a perfect complement that provides a quick reading.

In the hospital’s pharmacy, you will need to check the temperature in the refrigerator to avoid temperature fluctuations and variations in different areas. This way, you will maintain the drugs under stable conditions.

Types of thermometers

We have several general types of thermometers, which we explain below.Time and temperature indicators

They are adhesive labels that control the time a product is exposed to a temperature through a color change. They are useful for monitoring the conservation of vaccines and medicines, since they will alert us if they have been exposed to inappropriate temperatures for longer than they can withstand without degrading. They are a perfect, easy and inexpensive complement to guarantee compliance with the cold chain.Maximum-minimum thermometer

It has two columns of mercury – one with the maximum temperatures and one with the minimum ones. They both have a built-in graduated scale where we can observe the level of mercury and, therefore, the temperature at the time. This thermometer allows the control of variations of maximum and minimum temperatures reached in the refrigerator or the room. You will be able to see them in a different colour.

Adhesive thermometers

They are temperature labels that indicate the temperature of the area or surface to which they have been adhered by changing colour. They are easy to use and affordable.

Temperature recorder

It is an automatic device that takes makes temperature measurements based on time intervals. Thus, it allows you to obtain graphs and tables to observe the temperature variations.

Irreversible temperature indicators

They are a cost-effective alternative to the temperature recorder. These indicators change colour permanently when they reach specific temperatures. This way, we can check whether or not the critical temperature has been exceeded in a particular area.

In conclusion, we recommend hospital thermometers as an effective way of measuring temperature in the healthcare environment.