No products

Prices do not include tax.

Food safety: food temperature control

Maintaining the right food temperature is essential for its preservation. The right conditions, among others, are to guarantee stable cooling temperatures throughout the production chain. This cooling halts the food’s decomposition process. The microorganisms and enzymes involved in these processes become dormant or inactive thanks to low temperatures.

Without food temperature control, the modern food industry as we know it could not exist, and consumers would end up suffering from various diseases. So, to avoid these problems, the best thing is to understand the reasons behind effective temperature control in the food industry and how to carry it out easily.

Types of Food industry

- Cold chain

The technical standard of the cold chain

Information on the cold chain can be found in Regulation (EC) No 852/2004 of the European Parliament and of the Council of 29 April 2004 on the hygiene of foodstuffs. This regulation is designed to establish general rules for the hygiene of products and to guarantee their good condition. In this area is where we find the food cold chain.

The standard indicates that food cannot be stored at ambient temperature (between 15 and 30 °C). The reason behind this is simple. In this temperature range, microbes present in food will act at a higher speed, which can cause different food-borne diseases and the modification of the organoleptic characteristics of the product.How long does it take to break the cold chain?

The chain will break when the food loses the temperature indicated for its preservation. In this sense, for refrigerated products, the temperature should not exceed 5 °C. For frozen products, the temperature should not be above −18 °C. We must highlight that the temperature we are dealing with here is that of the food and not of the cold room.

Sometimes, measuring temperature wrong can lead to error, as the temperature in some areas of the chamber can be incorrect due to the location of the temperature sensors. It can also register transitory variations, without this affecting the food, which keeps its temperature.

To prevent these problems, we can use temperature labels, as they are stuck directly onto the product or pallet, ensuring that their measurements are real.

Also worth considering is the fact that, once the chain is broken, it cannot be fixed. For example, if a product is refrozen, ice crystals will form inside the food. These crystals can break down the muscle fibres in the meat and cause it to lose its characteristics.The importance of cold chain control

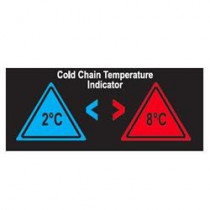

Controlling the cold chain is essential. To ensure that it does not break, using temperature control labels is quite useful. These labels react by changing colour when a specific temperature is exceeded. This way, you can see if the chain has been broken at a glance and act accordingly. They are ideal for storage and, most of all, to guarantee an unbroken cold chain during transport.

The use of cold chain thermometers helps us check the chain’s proper functioning. However, the only way to guarantee this is by using irreversible temperature indicators, which monitor the process from start to finish. Anyway, without a good understanding of the cold chain and its technical standard, we cannot act in an informed manner and take appropriate action. This is the only way to avoid breaking the cold chain and putting food at risk. - Food sterilization

Food cleaning and disinfection programmes

The food industry always works against the clock. Once an animal is butchered or a plant is harvested, it inevitably starts to rot.

Between the slaughterhouse or the crop field and the consumer’s home, there is a whole production chain that must ensure a safe preservation system. The implementation of methodologies based on industrial food sterilization programmes is the only guarantee to achieve these goals. Refrigeration is a useful way of preserving food, preventing or slowing down its deterioration. However, conducting a previous sterilization process is sometimes needed to make sure that pathogens are eliminated.

The use of irreversible temperature indicator labels guarantees that the food has passed the disinfection process and has reached the required temperature.

The most effective method for the sterilization of packaged foods is heat disinfection. This method involves heating the food and its containers up to temperatures that eliminate any microorganisms that may damage them. In this sense, food sterilization temperature ranges from 115 to 127 °C, depending on the type of food. This is high enough to ensure the complete annihilation of any common pathogens.

Temperature control and ensuring that the necessary temperatures are reached in these processes is vital, as errors can have serious health consequences. One of the several disinfection methods is the sterilization of preserves in an autoclave. These machines heat the preserves using water vapour above 100 °C and subject them to high pressure. High temperatures and water vapour together lead to the denaturation of proteins in microorganisms, contributing to an effective elimination.The HACCP protocol

HACCP stands for Hazard Analysis and Critical Control Points, a protocol followed by the food industry to ensure food safety and industrial food sterilization. It involves the identification, evaluation and prevention of contamination risks of food throughout the production chain.

The control of food sterilization temperatures is one of the main sections of this protocol. Temperature labels are an effective tool for the correct implementation of current regulations.

This tool guarantees the quality of food and ensures its preservation over time. It is a strict protocol that establishes self-control mechanisms, allowing for rapid action if there is an onset of a threat somewhere in the chain.

In short, disinfecting food is key in the modern food industry. This ensures that the entire population has access to food that is in good condition and has guaranteed quality standards. And all thanks to prevention.

Food industry Best seller

LCD reversible adhesive temperature indicator. This label changes colour on the basis of the temperature.

Reversible temperature indicator for the...44,49 €The TDI adhesive temperature label is an indicator coming with three irreversible temperature points. It has been specifically manufactured to control the sanitizing of industrial dishwashers.

TDI Label- TDI Thermometer for the control...314,27 €This product is supplied in packets with 10 thermometers. Irreversible-type temperature indicator with 8 temperature points. This is an adhesive thermometer than can be stuck on any surface or product. The points are marked with temperature in ºC and ºF.

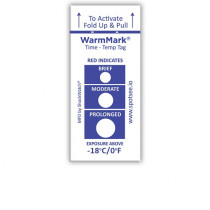

8-level irreversible thermometers (pack 10...15,93 €Irreversible time and temperature indicator by color change. This adhesive label alerts you to inappropriate temperature exposure by progressively changing the color of the control points. Each point is calibrated for a specific period of time, thus allowing control of the exposure time at that temperature.

WarmMark Time and Temperature (pack 100...238,00 €

Why food temperature control is important

The reason behind this control is no other than hygiene. Keeping low temperatures at all times stops bacteria from reproducing or kills them. These living organisms proliferate between 4 and 60 °C, to such an extent that in 20 minutes they are able to double the initial population. Therefore, we have to keep fresh and frozen food below those temperatures.Food safety: cold vs. heat

Using cold is necessary to market fresh food. While most bacteria begin to die or stop reproducing at 65 °C, subjecting food to this temperature involves cooking, which is not always possible.

However, subjecting food to a high-temperature process is another method used for its preservation, although this is not the case for fresh food. This way, fresh food should remain between 4 and −1 °C. In this range, bacteria stop reproducing and go dormant. Those that are less resistant disappear.

Food temperature: frozen food

When it comes to frozen food, it must be kept at −18 °C throughout the entire production chain. If the cold chain breaks, frozen food will be exposed to microbial growth, and it cannot be refrozen without its characteristics been affected. For example, refreezing a fillet steak will cause the water inside to form ice crystals, which will break down the tissues and cause the meat to lose most of its quality.Food thermometers

This is why food safety control is so important in the modern world. To ensure that safe temperatures have been in place, we recommend irreversible temperature labels that act as warning devices. These food temperature labels have a heat-sensitive dye that will permanently activate when a specific temperature is exceeded.

This allows an operator to know if the cold chain has been broken at any point in time and to take corrective action quickly and safely. The use of reversible adhesive thermometer labels also helps detect whether the current temperature is correct at a glance. This way, we can prevent food deterioration.

In short, taking care of the food temperature is a guarantee of hygiene and safety in the food industry. People greatly benefit from these practices, as they receive products that are safe to consume and that maintain their organoleptic properties intact. Without a doubt, this is massive progress for humanity.