No products

Prices do not include tax.

Temperature control for aluminium coating

Quality control in the manufacture of coated aluminium profiles requires checking the melting temperature of the resins on the aluminium. To do so, we must pay special attention to two of the stages of the aluminium coating process.

The drying and polymerisation stages require suitable temperature control to achieve a quality product. The result of the process depends to a great extent on the correct execution of these two stages. We will let you know all the details below.Main labels to control the temperature during the coating of aluminium

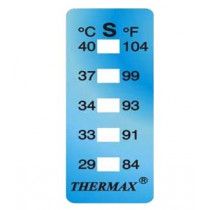

Irreversible temperature indicator with 5 indicating points. Supplied in packets with 10 units.

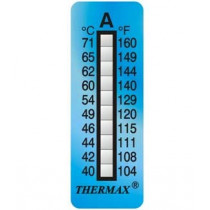

5-level irreversible thermometer (pack 10...13,61 €Irreversible thermometer with de 10 temperature points.. Supplied in packets with 10 units.

10-level irreversible thermometer (pack 10...19,15 €Irreversible-type temperature indicator. These temperature labels are adhesive and can be stuck on any surface or product. They change to permanent colour when reaching the marked temperature.

1-temperature irreversible thermometer...26,84 €Adhesive temperature labels with 6 control points are supplied in packets with 10 units.

6-level mini irreversible thermometer...14,63 €This product is supplied in packets with 10 thermometers. Irreversible-type temperature indicator with 8 temperature points. This is an adhesive thermometer than can be stuck on any surface or product. The points are marked with temperature in ºC and ºF.

8-level irreversible thermometers (pack 10...15,93 €

How to coat aluminium: process stages

The process of coating aluminium consists of the electrostatic application of powdered pigment to the metal’s surface. These pigments are polyester or polyurethane resins that will protect the finished profile against sunlight and corrosion caused by rain, humidity or other weather conditions that may affect it once installed. Additionally, coating offers a wide variety of paint colours that can be applied.

This process is the same whether we are coating bars, plates or whether we are coating aluminium rims. The stages of the entire process are detailed below:

- Profile cleaning.

- Removing any rust from the profile’s surface.

- Impregnating or priming with a solution that allows subsequent electrostatic adhesion of the powder paint.

- Drying the profiles for the next stage.

- Applying the pigment for its correct adherence to the metal profile.

- Thermal hardening of the applied pigment or polymerization.

It should be noted that all these processes have different temperature ranges. However, they do not cause harmful effects on the material, given the heat capacity of aluminium and its melting temperature.

Temperature control during the drying stage in aluminium coating

After the priming stage – one of the most essential steps in aluminium coating – the profiles to be coated must be dried to remove any residues of the applied solution. The solution is washed off with water. Then, the profiles are taken to a drying oven, where they are heated to approximately 120 °C for at least 15 minutes. For the correct polymerization of the applied resin-based paints, the aluminium must be subjected to a temperature between 180 and 200 °C for 20 minutes.

Self-adhesive heat-sensitive labels allow for unassisted, high-precision control in this stage. When the aluminium is removed from the oven, we can check the temperature reached by looking at the colour variation on the different levels on the labels. Since they are irreversible labels, they mark the temperature reached in the process, and can, therefore, guarantee the result.

Temperature control during the thermal hardening stage

Once the pigments have been applied to the profiles using electrostatic guns, the powder pigment will have completely adhered to the aluminium. The proper monitoring of the melting temperature of these resins on the aluminium profiles is very important to ultimately make sure that the maximum durability of the product has been achieved. By using a self-adhesive thermal label, we can see the maximum temperature reached and thus ensure the finished profile’s excellent quality.

Advantages of using temperature labels in aluminium coating

Self-adhesive thermal labels offer an easy, cost-effective solution to this problem. The main advantage is that, since the label is placed on the part itself, it guarantees that the reading obtained is the exact temperature the part was subjected to. This temperature can sometimes differ from that of the oven.

Temperature control systems used in the processes usually measure the heat generated inside the oven. However, making sure that this temperature is even in the entire space is quite tricky. By using thermal labels, we can check that the process is performed properly.