No products

Prices do not include tax.

Time and temperature for sterilization in an industrial autoclave

A sterilization autoclave is a thick-walled, hermetically-sealed metal container in which surgical instruments or other materials can be disinfected using high pressure. The autoclave sterilization temperature must be appropriate, otherwise, it will not serve its purpose.

The operation of an industrial autoclave and a laboratory autoclave are not far apart. In both cases, the combined action of steam and heat will cause the denaturation of proteins in microorganisms, which are essential for them to live and reproduce. Therefore, these microorganisms will be destroyed.Their operation generates water vapour and restricts its output in order to reach a pressure inside the autoclave that is above atmospheric pressure. This will heat the steam to approximately 120 °C.

Main sensors for temperature control in autoclaves

The TDI adhesive temperature label is an indicator coming with three irreversible temperature points. It has been specifically manufactured to control the sanitizing of industrial dishwashers.

TDI Label- TDI Thermometer for the control...314,27 €Irreversible-type temperature indicator. These temperature labels are adhesive and can be stuck on any surface or product. They change to permanent colour when reaching the marked temperature.

1-temperature irreversible thermometer...26,84 €Circular-type irreversible temperature label. Supplied in packets with 10 units.

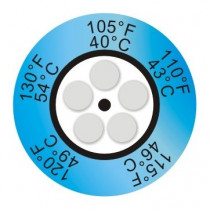

Clock-type irreversible thermometer with 5...16,69 €This product is supplied in packets with 10 thermometers. Irreversible-type temperature indicator with 8 temperature points. This is an adhesive thermometer than can be stuck on any surface or product. The points are marked with temperature in ºC and ºF.

8-level irreversible thermometers (pack 10...15,93 €

Sterilization times and temperatures

The most widely used sterilization method is steam because it is non‑toxic and is cost‑effective, fast and efficient if used according to the manufacturer’s specifications. For this method to be effective, there must be steam saturation and absence of air (the pressure itself is not a key factor in this process, although it is a way of reaching a high temperature).To sterilize metal materials with pressurized steam in an autoclave, the recommended temperature and time are:

- 115 °C, half an hour.

- 121 °C, 15 minutes.

- 126 °C, 10 minutes.

- 134 °C, between 3 and 5 minutes.

Examples of materials, temperatures and times for sterilization in autoclave

- To sterilize surgical material, you will need at least 20 to 30 minutes at 121 °C.

- Glass items (like laboratory flasks) will need 20 minutes at 121 °C.

- Cotton garments and fabrics will need 30 minutes at 121 °C.

Temperature labels to guarantee the temperature of sterilization in the autoclave

Temperature labels are devices that contain several heat-sensitive indicators. They can be of two types: reversible and irreversible.The first ones can change as needed to indicate the current temperature and can be used several times. The second type are self-adhesive sensors with several small sealed and heat-resistant indicators that turn black when they reach the temperature indicated on the label. By permanently changing, they allow us to check the temperature reached during sterilization.

In short, the industrial sterilization autoclave is widely used in different sectors, such as the woodworking, food, textile, tyre manufacture and hospital sectors, and is very effective in eliminating microorganisms.