No products

Prices do not include tax.

Beer thermometer

Adhesive beer thermometers are one of the most suitable alternatives for the thermal control of the craft beer brewing process. Proper thermal monitoring is essential at several stages of production, so accurate temperature sensors are fundamental.

By combining reversible and irreversible thermometers, you can achieve full temperature control and monitoring ranging from 74 °C, which can be reached in the initial mashing stage, to 8 °C, a temperature that may be needed for quick cooling, depending on the type of beer. During this process, beer also goes through different intermediate temperatures, until its final bottling and marketing.

The best beer thermometers

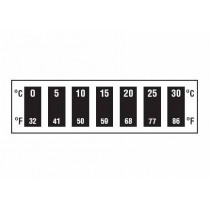

Horizontal adhesive thermometer with 7 temperature points changing their colour to display the temperature detected. It can be supplied in packs of 10 units. This thermometer is displayed in ºC and ºF.

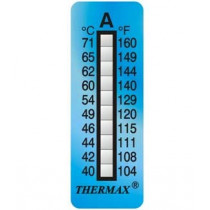

7 level adhesive LCD thermometer (pack 10...13,31 €Irreversible thermometer with de 10 temperature points.. Supplied in packets with 10 units.

10-level irreversible thermometer (pack 10...19,15 €

Irreversible temperature control in the first stage of craft beer production

After obtaining the initial mixture of ingredients, including the appropriate amount of water and malt, depending on the beer, the first stage that requires a beerthermometeris the mashing.

Temperature and mashing time are decisive in determining the body of the beer, its malty flavour, its foam quality, etc. Temperatures at this point are usually between 50 °C and 70 °C, approximately. Therefore, for this stage, we suggest the THERMAX 10 levels Range A (40-71 °C). This thermometer allows unassisted control in the mash tun since the reached temperature will be permanently marked on the label.

Reversible temperature control in the second stage of craft beer production

After the mashing, it undergoes a fast cooling process using heat exchangers to reach the fermentation temperature. In this brewing stage, different temperatures may be required depending on the type of beer being produced:- Lager beers: 8-10 °C

- Ale-type beers: 18-20 °C

In this stage, we suggest the use of a reversible beer thermometer, model TLC7 Range 2 (0-30 °C), as you monitor the temperature inside the container at all times.

Reversible temperature control in the last stage of craft beer production

The last stage before bottling is its ageing at cellar temperature and without sunlight. The temperature is of around 12 °C. This process will be shorter or longer, depending on the type of beer. Our reversible beer thermometer lets us know the temperature of our containers or vessels at all times.

Advantages of adhesive beer thermometers

Among the many features of beer thermometers, we can highlight the following:

- High accuracy in temperature measurement: the thermometeritself is adhesive, so it sticks directly to the beer tun and detects the actual temperature.

- High precision: it displays the precise temperature with a highly-accurate reading.

- Easy to use: as with any other sticker, you just have to make sure that the surface to which you are going to stick the thermometer is free of dust, grease or moisture.

- Affordable solution: compared to other types of sensors, these craft beer thermometers allow you to control the fermentation temperature of beer at an unbeatable value for money.

- No batteries needed: the beer thermometer does not interfere with the electrical parts or electronic components of our craft beer equipment.