No products

Prices do not include tax.

Furnace temperature control system

Countless manufacturing processes require, in one or more of their stages, the temperature control of an industrial furnace.Having suitable sensors is essential in these stages, where temperature is a key factor. An industrial furnace can reach quite divergent temperatures, so using the same kind of indicator will not always be possible. We have irreversible labels and crayons to measure the temperature inside the furnace and, what is more, directly on the parts being manufactured. Unwanted temperature fluctuations can, therefore, be detected in inaccessible areas.

Main products for temperature control in industrial furnaces

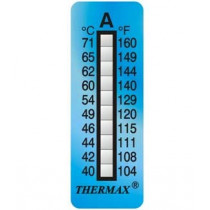

This product is supplied in packets with 10 thermometers. Irreversible-type temperature indicator with 8 temperature points. This is an adhesive thermometer than can be stuck on any surface or product. The points are marked with temperature in ºC and ºF.

8-level irreversible thermometers (pack 10...15,93 €Irreversible-type temperature indicator. These temperature labels are adhesive and can be stuck on any surface or product. They change to permanent colour when reaching the marked temperature.

1-temperature irreversible thermometer...26,84 €Thermal pencil for controlling temperatures. These wax-based pencils with heat-sensitive ink allow to mark any surface, which will change colour depending on the temperature.

Heat-sensitive pencil (10 units)125,45 €Adhesive temperature labels with 6 control points are supplied in packets with 10 units.

6-level mini irreversible thermometer...14,63 €Irreversible thermometer with de 10 temperature points.. Supplied in packets with 10 units.

10-level irreversible thermometer (pack 10...19,15 €

Temperatures we can control with irreversible thermometers

When the temperature control range of an industrial furnace does not exceed 290 °C, we can use irreversible heat-sensitive labels. These indicators are the most cost-effective, simple and accurate option we can use – depending on the temperature range. Choose a clean, dry area of the part where to stick the label before placing it inside the oven. At the end of the process, we will see what has happened. We can even< remove the label to attach it to a report if needed for quality control purposes.

Temperatures we can control with temperature crayons

When labels cannot be used – either because the parts are too small and there is not enough space to stick them on, or because the temperature reached is over 290 °C – a good temperature control system for a furnace is the use of heat-sensitive crayons. With this option, we will cover a temperature range of 120 to 600 °C. It is also quite easy to use. Because it is a wax crayon, we can mark the pieces conveniently without needing much space. In this case, if we have marked a part that we will include in our sales inventory, we will have to remove the line, which can be done by simply using sandpaper – manually or mechanically. If we were able to place a part made of the same material or a testing part in the same furnace, we could skip this step.

Advantages of internal thermal control in an industrial furnace

- Detecting possible faults such as leaks, hot spots or temperature imbalances.

- Accurately diagnosing the temperature.

- Reducing extra costs on fuel or electrical power.

- Following the established quality guidelines.

- Improving the quality of the final product and ensuring customer satisfaction.