No products

Prices do not include tax.

Transport of refrigerated and frozen food

Maintaining the cold chain for refrigerated and frozen food is essential so as not to compromise the preservation of the food and, therefore, the consumer's health. Food must be kept at a constant temperature, as any fluctuations in the allowed limits can irreversibly damage the products, even if they subsequently return to the correct temperature.

One of the critical links in this chain is transport. An unsuitable vehicle, poor handling, and negligent loading or unloading of goods can cause a loss of temperature. Methods for the preservation of refrigerated food and frozen food must be strictly applied, and the utmost care must be taken.

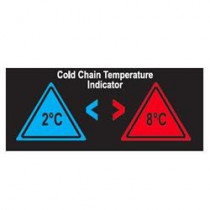

The following are the temperature indicators commonly used to control the cold preservation of food during transport:

The best temperature labels for refrigerated food transport

LCD reversible adhesive temperature indicator. This label changes colour on the basis of the temperature.

Reversible temperature indicator for the...44,49 €Irreversible-type temperature indicator. These temperature labels are adhesive and can be stuck on any surface or product. They change to permanent colour when reaching the marked temperature.

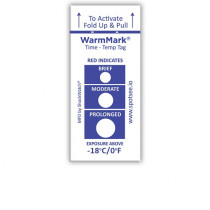

1-temperature irreversible thermometer...26,84 €Irreversible time and temperature indicator by color change. This adhesive label alerts you to inappropriate temperature exposure by progressively changing the color of the control points. Each point is calibrated for a specific period of time, thus allowing control of the exposure time at that temperature.

WarmMark Time and Temperature (pack 100...238,00 €The FREEZESAFE temperature drop indicator is an adhesive label that, by means of a color change, alerts us that the temperature has dropped below a critical value. The color change is permanent and irreversible, so it acts as a control indicator, recording the event. It is supplied in packs of 100 units.

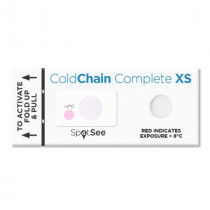

FREEZESAFE temperature drop indicator...193,00 €Coldchain complete XS is a temperature label for cold chain control. This indicator is irreversible and alerts us by means of a color change if a product has been exposed outside the required temperature range, both above and below it. It is supplied in packs of 100 units.

Coldchain Complete XS cold chain...322,00 €

Food cold chain: transport of frozen food

Maintaining the food cold chain is essential at all stages, even when the product reaches the consumer. However, transport will always be the critical point par excellence. Taking care of the temperature is essential – for frozen products, it should remain at around −18 °C.Control methods for the preservation of refrigerated food

The main problem during transport is ensuring that conditions are maintained along the journey. Adhesive thermometer labels can be used in trucks and vans to control any increases in temperature during transport. Once these adhesive labels are stuck to the goods, they will accurately alert if the critical temperature has been exceeded. Later on, when unloading, you can check if the conditions were suitable, and if the food cold chain were respected.Vehicles for refrigerated food

The vehicles used – isothermal vehicles – are specially designed to maintain the temperature along the entire journey. They are vital in allowing refrigerated food to remain in good condition until it reaches its destination. These vehicles have a special interior lining, cooling devices and specific containers so that each product can be transported with every guarantee.Refrigerated food

Fresh food, not frozen, requires temperatures that do not exceed 7 °C. This way, microorganisms go into a dormant stage and the enzymes that break down the food slow down their activity.

In this case, a specific vehicle is also required to maintain a stable temperature and airflow that ensures even distribution.

The most significant risk in these cases is the change in temperature depending on the loading area. It would be useless if one part of the compartment was at 7 °C and the rest of it was at 10 °C. Since they are physically stuck to the products, temperature labels can easily alert of the risk and prevent the deterioration of the goods.