No products

Prices do not include tax.

Temperature recorder in food production processes

In short, recording the temperature of food lets us know if it is being handled and preserved properly. It is a matter of hygiene that can affect the health of thousands of people. One single mistake when it comes to food handling can cause a major health problem and a serious liability for the breaching company.

Main thermometers used to record temperatures in the food industry

LCD reversible adhesive temperature indicator. This label changes colour on the basis of the temperature.

Reversible temperature indicator for the...44,49 €Irreversible-type temperature indicator. These temperature labels are adhesive and can be stuck on any surface or product. They change to permanent colour when reaching the marked temperature.

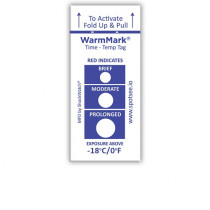

1-temperature irreversible thermometer...26,84 €Irreversible time and temperature indicator by color change. This adhesive label alerts you to inappropriate temperature exposure by progressively changing the color of the control points. Each point is calibrated for a specific period of time, thus allowing control of the exposure time at that temperature.

WarmMark Time and Temperature (pack 100...238,00 €The FREEZESAFE temperature drop indicator is an adhesive label that, by means of a color change, alerts us that the temperature has dropped below a critical value. The color change is permanent and irreversible, so it acts as a control indicator, recording the event. It is supplied in packs of 100 units.

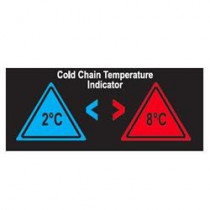

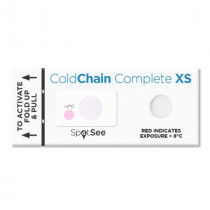

FREEZESAFE temperature drop indicator...193,00 €Coldchain complete XS is a temperature label for cold chain control. This indicator is irreversible and alerts us by means of a color change if a product has been exposed outside the required temperature range, both above and below it. It is supplied in packs of 100 units.

Coldchain Complete XS cold chain...322,00 €

Temperature in food production

Food production has always faced a challenge: food preservation. Given its perishable nature, food tends to rot over a period of time. To delay this effect, the use of cold is a requirement. Cold slows down the action of those agents responsible for food decomposition. Thus, bacteria and enzymes slow down or halt their activity, as is the case with freezing.The two main methods used in food production processes are refrigeration and freezing. The first of them is achieved by keeping the food between 0 and 4 °C; the second one requires a temperature of −18 °C for effective preservation. Although these numerical values are generally accepted standards, each food has its own suitable preservation temperature.

For example, milk should be kept between 4 and 12 °C when the carton has not yet been opened. Cheese should be kept between 2 and 4 °C, as is the case with pasteurized milk. As for meat, ham and chicken, they can last between 10 and 15 days without a problem if they are preserved at 0 °C. However, vegetables must be kept at temperatures between 2 and 5 °C, but they need to be consumed in a few days as they are quite delicate.

Adhesive temperature recording labels

Time and temperature labels

These adhesive indicators are the ideal solution for registering food temperatures. They work by changing color when a temperature is exceeded for a specified amount of time. This type of control emulates what would be the deterioration process of many refrigerated foods in the event of poor conservation. That is, they will alert us if the product has been exposed to temperature for longer than it supports without deteriorating. They are inexpensive and simple to use, being an alternative or complement to temperature loggers.Irreversible temperature indicators

To maintain these temperatures at all times, from the time the food is acquired until it reaches the consumer, using a food temperature recorder is necessary to guarantee that the preservation temperature has been respected. Irreversible thermometers are a simple and inexpensive method to record temperatures. They can be left in a cold room or supermarket refrigerator to indicate whether the maximum temperature has been exceeded at some point.Reversible temperature indicators

There are also temperature labels that display the current numerical value at all times. This way, operators can check values at a glance, which speeds up the detection of a potential problem and the decision making if safety levels in the food production processes have been exceeded.In a few words, a temperature recorder is indispensable in the food industry. Thanks to adhesive thermometers, it is possible to keep cold temperatures under control easily and affordably and to ensure that the food is kept at appropriate preservation values. Therefore, a temperature recorder, like an adhesive label, is an excellent ally in the food industry.