No products

Prices do not include tax.

Temperature control: industrial temperature sensors and indicators

To correctly perform temperature control in industrial processes, we can avail of a wide variety of devices. Most of them report the temperature reached in a machine, a furnace or a specific area. However, sometimes it is preferable to control the exact temperature a part receives. In these cases, heat-sensitive adhesive labels are especially useful.

Types of Industry

- Industrial furnaces temperature

Temperatures we can control with irreversible thermometers

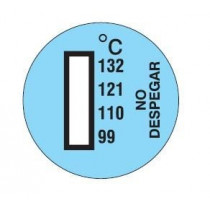

When the temperature control range of an industrial furnace does not exceed 290 °C, we can use irreversible heat-sensitive labels. These indicators are the most cost-effective, simple and accurate option we can use – depending on the temperature range. Choose a clean, dry area of the part where to stick the label before placing it inside the oven. At the end of the process, we will see what has happened. We can even< remove the label to attach it to a report if needed for quality control purposes.

Temperatures we can control with temperature crayons

When labels cannot be used – either because the parts are too small and there is not enough space to stick them on, or because the temperature reached is over 290 °C – a good temperature control system for a furnace is the use of heat-sensitive crayons. With this option, we will cover a temperature range of 120 to 600 °C. It is also quite easy to use. Because it is a wax crayon, we can mark the pieces conveniently without needing much space. In this case, if we have marked a part that we will include in our sales inventory, we will have to remove the line, which can be done by simply using sandpaper – manually or mechanically. If we were able to place a part made of the same material or a testing part in the same furnace, we could skip this step.

Advantages of internal thermal control in an industrial furnace

- Detecting possible faults such as leaks, hot spots or temperature imbalances.

- Accurately diagnosing the temperature.

- Reducing extra costs on fuel or electrical power.

- Following the established quality guidelines.

- Improving the quality of the final product and ensuring customer satisfaction.

- Manufacture of photovoltaic modules

Critical temperature in the manufacture of solar panels: 132 °C

During the manufacture of solar panels, the ideal temperature to be reached in the polyester and glass melting stage is 132 °C. It has been proven that this temperature enables the perfect union between both components and ensures the perfect watertightness of the assembly. Watertightness is crucial for the panel to be 100% effective when it is put into service.

Advantages of using temperature labels in the manufacture of solar panels

- In the manufacture of photovoltaic solar panels, self-adhesive indicators allow the direct and unassisted control on the surface at issue. These indicators are placed at the beginning of the process. When it has finished, they allow us to check it the panel was subjected to a suitable temperature. Since they are irreversible indicators, they permanently change colour.

- The single-dot temperature label specifically allows it to be placed in small areas, as it does not require much space.

- It does not need batteries. Therefore, this indicator does not interfere with electrical circuits or enclosures which the panels go through during their manufacture.

- Cost-effective solution. Since daily checks are needed to secure the manufacturing process of photovoltaic modules, self-adhesive thermal labels are a low-cost solution that is easy to implement. These temperature sensors can be supplied in rolls of 3000 units, making them easy to handle and allowing an even lower price without performance loss.

- They are somewhat flexible so they can adhere to curved surfaces.

- Given their nature, they can be attached to quality check reports at the end of the process.

- Manufacture of food cans

Quality control in the manufacture of aluminium cans

Quality control in the manufacture of food cans is an essential requirement for health reasons. In the manufacturing processes of any elements or accessories related to consumer products or items that come into contact with living beings, making sure that they comply with current regulations is necessary. Health requirements, HACCP protocols, etc. have been revised and perfected in recent times to prevent the development of viruses and bacteria due to undesirable contamination in packaged products.

A food can that has deteriorated or been damaged by faulty welding can be particularly dangerous for consumption. The germs that develop inside it could pose a threat to living beings and even be fatal.

The improvement of these containers – besides the use of new lighter metals, stainless metals like aluminium, and less rigid and alterable like brass – is largely due to better quality control.

Self-adhesive temperature labels have contributed to a much more reliable and accurate temperature reading. They are a more cost-effective solution than other sensorsAdvantages of using heat-sensitive labels in the manufacture of food cans

- These labels allow for unassisted temperature control since they enter the production line adhered to a can and do not need supervision until the end. Since these labels are irreversible and permanently change colour, it is at the end when we can see the result.

- Because these labels are placed directly onto the product and thanks to their high measurement accuracy, the readings are 100% reliable.

- They are made of self-adhesive paper, which makes them flexible so they can adhere to curved items.

- They are a low-cost sensor compared to other temperature indicators.

- They do not require batteries. Therefore, they do not interfere with electronics or electrical panels involved in the manufacturing process of beverage cans.

- Aluminium coating

How to coat aluminium: process stages

The process of coating aluminium consists of the electrostatic application of powdered pigment to the metal’s surface. These pigments are polyester or polyurethane resins that will protect the finished profile against sunlight and corrosion caused by rain, humidity or other weather conditions that may affect it once installed. Additionally, coating offers a wide variety of paint colours that can be applied.

This process is the same whether we are coating bars, plates or whether we are coating aluminium rims. The stages of the entire process are detailed below:

- Profile cleaning.

- Removing any rust from the profile’s surface.

- Impregnating or priming with a solution that allows subsequent electrostatic adhesion of the powder paint.

- Drying the profiles for the next stage.

- Applying the pigment for its correct adherence to the metal profile.

- Thermal hardening of the applied pigment or polymerization.

It should be noted that all these processes have different temperature ranges. However, they do not cause harmful effects on the material, given the heat capacity of aluminium and its melting temperature.

Temperature control during the drying stage in aluminium coating

After the priming stage – one of the most essential steps in aluminium coating – the profiles to be coated must be dried to remove any residues of the applied solution. The solution is washed off with water. Then, the profiles are taken to a drying oven, where they are heated to approximately 120 °C for at least 15 minutes. For the correct polymerization of the applied resin-based paints, the aluminium must be subjected to a temperature between 180 and 200 °C for 20 minutes.

Self-adhesive heat-sensitive labels allow for unassisted, high-precision control in this stage. When the aluminium is removed from the oven, we can check the temperature reached by looking at the colour variation on the different levels on the labels. Since they are irreversible labels, they mark the temperature reached in the process, and can, therefore, guarantee the result.

Temperature control during the thermal hardening stage

Once the pigments have been applied to the profiles using electrostatic guns, the powder pigment will have completely adhered to the aluminium. The proper monitoring of the melting temperature of these resins on the aluminium profiles is very important to ultimately make sure that the maximum durability of the product has been achieved. By using a self-adhesive thermal label, we can see the maximum temperature reached and thus ensure the finished profile’s excellent quality.

Advantages of using temperature labels in aluminium coating

Self-adhesive thermal labels offer an easy, cost-effective solution to this problem. The main advantage is that, since the label is placed on the part itself, it guarantees that the reading obtained is the exact temperature the part was subjected to. This temperature can sometimes differ from that of the oven.

Temperature control systems used in the processes usually measure the heat generated inside the oven. However, making sure that this temperature is even in the entire space is quite tricky. By using thermal labels, we can check that the process is performed properly.

- Interlining fusion process

Main recommendations for the correct use of a heat-activated adhesive interlining

Before starting, it is very important to have a machine that is in good condition and properly calibrated. Only a balances combination of temperature, pressure and time can guarantee perfect adhesion of the fusible interlining. For this reason, the temperature must be checked daily on the entire area that is subjected to pressure, and every time the machine is stopped. Temperature readings are best taken when the machine is empty, before it is put into service for the day. Production should not start until this assessment has been made, and the pressure, time and temperature have been set.

Main causes of adhesion failure in fusible interlining

There are 2 reasons why a heat-activated thermal interlining can fail:

- The interlining wholly or partly detaches from the fabric.

- The main fabric is wrinkled where the interlining has adhered.

Advantages of controlling the temperature of interlining with heat-sensitive strips

- “In situ” temperature measurement: the strips are usually placed between the fabric and the interlining. This way, they will measure the temperature right in the between the heat-activated adhesive interlining and the fabric.

- The strips serve as certification, i.e. after the process has ended, they can be removed and attached to quality control documentation.

- The textile strips are flexible; they adapt entirely to the structure of the piece without causing any deformities.

- They do not require batteries and therefore do not interfere with the electronic or electrical components that are part of the machinery.

- The heat-sensitive strips provide highly-accurate readings.

- Manufacture of mechanical parts

Issues when controlling the temperature in industrial thermal processes

In the manufacturing of parts, reliable temperature control is essential to ensure that the product goes through the thermal process correctly and, therefore, has the correct features that guarantee the quality of its finishing.

The problem in continuous and static ovens is the use of sensors that monitor the temperature inside the oven itself, but not the temperature of the actual part. Due to the use and wear and tear of the heating resistors, temperature variations inside the oven are quite frequent.

Also, due to wear and tear, the oven temperature sensors can perform faulty readings and need to be replaced or recalibrated.

The use of temperature indicators is a simple solution to this problem.

Temperature indicators for the manufacture of mechanical parts and vulcanized products

Irreversible temperature labels are adhesive sensors that stick to a part and permanently change colour when a specific temperature is reached. When attached to the product, these labels will give us the exact temperature to which the part has been subjected. Additionally, since they are irreversible, at the end of the process we can check if the correct temperature has been reached or not.

Using these temperature indicators makes it possible to detect problems in areas of the oven that are not properly heated, or inaccuracies of the oven’s own temperature sensors due to wear and tear. This allows us to correct the defects and guarantee the quality of the parts. Because these labels are adhesive, they can be removed later on and attached to quality reports.

Temperature crayons

At temperatures above 260 °C, using temperature labels is not possible. However, it is plausible to use temperature crayons for thermal control. These crayons are easy to use, just like the labels. Simply mark the parts to be monitored, and the stroke we make with the crayon will permanently change colour during the process. This will indicate whether or not the right temperature has been reached.Temperature control in the vulcanization of rubber

In the manufacture of parts, one of the processes that require temperature control to guarantee the final product is the vulcanization of rubber, both in the manufacture of tires and the verification of rubber seals.Temperature control in the manufacture of tires

During the manufacture of tyres, several thermal processes require the measurement of the working temperature.

During belt and ply calendering, when the rubber compound is applied to the beads, and when the tire is curing, it is important to control the process temperature.

However, it is during the mixing of the rubber compound where temperature monitoring is critical, as excess heat can damage it. This operation is usually carried out in two stages, the mixing stage, where the temperature ranges between 160 °C and 170 °C, and the final stage, in which the curing materials are added. This final stage cannot exceed 100 °C-110 °C to prevent the material from burning.

Temperature control in the verification of rubber seals

This process requires monitoring and recording of the temperature reached to ensure that the seals will subsequently have the appropriate hardness. The rubber seals must ensure that specific components of the car engine are hermetically sealed to prevent the leakage of the fluids involved in the proper functioning of the engine (brakes, antifreeze, etc.). The process is carried out at 120 °C, and the use of temperature indicators or crayons guarantees the final result.

Temperature recording in the manufacture of mechanical parts: annealing

There are various processes in the industry aimed at changing the properties of metal and, therefore, the characteristics of the part. Annealing is a treatment designed to increase the resistance and elasticity of the part. It is done by eliminating the internal stress that occurred in other processes like tempering.

Temperature control in annealing varies depending on the part and the use that is required. Therefore, parts that need increased hardness, such as tools, are usually subjected to temperatures of 150 °C to 220 °C. In comparison, products that need greater elasticity are subjected to temperatures between 450 °C and 600 °C.

In any of these procedures, using temperature indicators to control the temperature in the manufacture of industrial parts is the most effective way to ensure the final product’s quality.

Industry Best seller

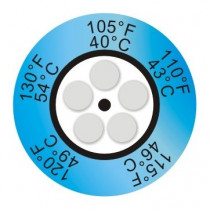

This irreversible temperature indicator has been designed to control overheating in engine parts. It contains 4 control points changing their colour permanently when the temperature stamped on them is reached. As this change is irreversible, this indicator is able to detect whether the said temperature has been reached anytime in the area where it has...

Temperature Recorder control of engine...29,50 €This product is supplied in packets with 10 thermometers. Irreversible-type temperature indicator with 8 temperature points. This is an adhesive thermometer than can be stuck on any surface or product. The points are marked with temperature in ºC and ºF.

8-level irreversible thermometers (pack 10...15,20 €Circular-type irreversible temperature label. Supplied in packets with 10 units.

Clock-type irreversible thermometer with 5...15,93 €Irreversible-type temperature indicator. These temperature labels are adhesive and can be stuck on any surface or product. They change to permanent colour when reaching the marked temperature.

1-temperature irreversible thermometer...25,61 €Thermal pencil for controlling temperatures. These wax-based pencils with heat-sensitive ink allow to mark any surface, which will change colour depending on the temperature.

Heat-sensitive pencil (10 units)119,70 €

Uses of industrial temperature control

Below we mention different uses in which temperature adhesive labels are a simple and affordable solution to control the temperature in industrial processes. These products have proven their effectiveness in various fields of use:Temperature control for aluminium coating in industrial furnaces

To coat aluminium, we need to apply a uniform layer of powder resin paint on this material. To achieve the melting and polymerization of the paint on the aluminium profiles, the furnace must reach 200 °C. Knowing the temperature the aluminium receives is important for the process to be carried out correctly during the polymerization process.

The adhesive temperature labels adhere directly to the parts, so they will indicate exactly the temperature they receive. Since they are irreversible, they allow us to check whether the desired temperature has been reached at the end of the process. This way, the process application can be controlled quite accurately.Industrial temperature indicator in photovoltaic module manufacturing

To guarantee the melting of the polyester with purified silicon crystals and to achieve their watertightness as a whole, the furnace must reach a temperature of 132 °C. By using adhesive temperature indicators, we can be sure of the heat received by the assembly and, therefore, of the correct melting of the polyester and silicon crystals. These adhesive industrial temperature sensors are a guarantee of a correct heating treatment.

Industrial temperature control in food can manufacturing

The manufacturing of cans consists of the following: once the parts of the can have been welded, they must be introduced into a flame furnace to guarantee the watertightness using a heating process. In this process, the cans must progressively reach 250 °C inside the furnace.

Making sure the cans reach this temperature is fundamental. Otherwise, they may not be watertight, which would result in poor food preservation. By using suitable industrial temperature measuring instruments, such as irreversible adhesive thermometers, we can guarantee the temperature reached. Checking that the temperature dots have changed appropriately at the end of the process is sufficient.

Industrial temperature sensor for mechanical parts

In the manufacture of industrial parts, heating treatment may be required to achieve a specific degree of flexibility or hardness. The lack or excess of heat in these treatments can cause breakage or produce parts without the required quality features.

Using adhesive temperature sensors, such as heat-sensitive labels, guarantees that the part has reached a specific temperature and, therefore, the correct unfolding of the manufacturing process.

As you have seen in the above cases, using an industrial temperature indicator is essential in some manufacturing processes that involve heating. Otherwise, guaranteeing sufficient quality within the industry would not be possible.