No products

Prices do not include tax.

Thermometer to control the food cold chain

The cold chain is essential to ensure food preservation. If the cold chain is not followed correctly, it would not be possible to transport fresh and frozen food over long distances.

A cold chain thermometer is indispensable to keep the cold chain unbroken from the moment food is obtained to the moment it is delivered to the end consumer. Only with proper temperature control can we ensure its compliance.

Therefore, the cold chain is the guarantee of good food preservation, be it a piece of meat or fresh vegetables. You need to know how it works and the regulations that apply in Spain so that you can understand it in depth.

Types of Cold chain

- Food Transport

Food cold chain: transport of frozen food

Maintaining the food cold chain is essential at all stages, even when the product reaches the consumer. However, transport will always be the critical point par excellence. Taking care of the temperature is essential – for frozen products, it should remain at around −18 °C.Control methods for the preservation of refrigerated food

The main problem during transport is ensuring that conditions are maintained along the journey. Adhesive thermometer labels can be used in trucks and vans to control any increases in temperature during transport. Once these adhesive labels are stuck to the goods, they will accurately alert if the critical temperature has been exceeded. Later on, when unloading, you can check if the conditions were suitable, and if the food cold chain were respected.Vehicles for refrigerated food

The vehicles used – isothermal vehicles – are specially designed to maintain the temperature along the entire journey. They are vital in allowing refrigerated food to remain in good condition until it reaches its destination. These vehicles have a special interior lining, cooling devices and specific containers so that each product can be transported with every guarantee.Refrigerated food

Fresh food, not frozen, requires temperatures that do not exceed 7 °C. This way, microorganisms go into a dormant stage and the enzymes that break down the food slow down their activity.

In this case, a specific vehicle is also required to maintain a stable temperature and airflow that ensures even distribution.

Loading and unloading are also critical points. Staff is responsible for keeping food refrigerated during this process. To do so, handling should be done quickly or carried out in refrigerated areas.

The most significant risk in these cases is the change in temperature depending on the loading area. It would be useless if one part of the compartment was at 7 °C and the rest of it was at 10 °C. Since they are physically stuck to the products, temperature labels can easily alert of the risk and prevent the deterioration of the goods.Refrigerated food transport: final considerations

In short, refrigerated and frozen food require specific conditions that must be kept stable over time. Both in the transport of refrigerated food and the transport of frozen foods, if temperatures are not maintained, the cold chain breaks and the end consumer's health is put at risk. - Food preservation

Refrigeration techniques and temperatures

These techniques are preferably used to preserve vegetables, fruit, fish, meat and seafood. When these are to be marketed fresh, there is no other possibility than to delay their deterioration using cold. To do so, they are subjected to temperatures that are close to and below zero degrees. These are the main methods.Freezing food

This procedure is the one that guarantees a more extended preservation period. However, in some cases, the product may lose its properties. In the process of freezing food, temperatures range from below 0 °C and to −18 °C. This ensures that the enzymes that break down the food slow down or halt their activity, killing the vast majority of the microorganisms.

However, this preservation method requires transport and storage facilities that are equipped to provide suitable temperature conditions. Having a reliable solution for temperature control is also important to guarantee that the food cold chain has not been broken at any time and ensure the food’s preservation.Refrigerated food

Refrigerated food is that which is kept at a temperature above 0 °C, but below 7 °C. The aim is to preserve the products’ freshness, which is achieved by slowing down the activity of the agents that break them down. The storage period of refrigerated food is shorter than that of frozen food. However, refrigeration allows a higher degree of product freshness. Again, controlling the refrigeration temperature of the food is necessary for proper preservation. Adhesive thermometer labels are a perfect solution since they are easily visible.Food preservation through heat

Heat is a powerful weapon to preserve packaged foods. When it comes to milk or preserves, high temperatures are used to eliminate microorganisms, some as dangerous as the Clostridium botulinum bacteria. The most commonly used techniques are the following.Sterilization

This technique is used for packaged food, which is subjected to temperatures of more than 115 °C. Microorganisms, spores and germs are eliminated without a trace, although it does affect the food’s properties. Ensuring that the sterilization temperature is reached through a reliable control method is essential to ensure food safety before the food storage process.Pasteurization

In pasteurization, high temperatures of around 80 °C are applied to inactivate the germs that are present in food. However, the existing spores are not eliminated. This is why the products need to be consumed within around three days and stored in the fridge to be kept cool. This method, nonetheless, does not affect the properties of the food.

In short, these are the main commonly-used food preservation methods. In all of them, controlling food preservation temperatures is essential to guarantee the storage period, as well as the chance of transporting them over long distances and enjoying them without unaltering their properties. - Temperature record

Temperature in food production

Food production has always faced a challenge: food preservation. Given its perishable nature, food tends to rot over a period of time. To delay this effect, the use of cold is a requirement. Cold slows down the action of those agents responsible for food decomposition. Thus, bacteria and enzymes slow down or halt their activity, as is the case with freezing.

The two main methods used in food production processes are refrigeration and freezing. The first of them is achieved by keeping the food between 0 and 4 °C; the second one requires a temperature of −18 °C for effective preservation. Although these numerical values are generally accepted standards, each food has its own suitable preservation temperature.

For example, milk should be kept between 4 and 12 °C when the carton has not yet been opened. Cheese should be kept between 2 and 4 °C, as is the case with pasteurized milk. As for meat, ham and chicken, they can last between 10 and 15 days without a problem if they are preserved at 0 °C. However, vegetables must be kept at temperatures between 2 and 5 °C, but they need to be consumed in a few days as they are quite delicate.Adhesive temperature recording labels

Time and temperature labels

These adhesive indicators are the ideal solution for registering food temperatures. They work by changing color when a temperature is exceeded for a specified amount of time. This type of control emulates what would be the deterioration process of many refrigerated foods in the event of poor conservation. That is, they will alert us if the product has been exposed to temperature for longer than it supports without deteriorating. They are inexpensive and simple to use, being an alternative or complement to temperature loggers.Irreversible temperature indicators

To maintain these temperatures at all times, from the time the food is acquired until it reaches the consumer, using a food temperature recorder is necessary to guarantee that the preservation temperature has been respected. Irreversible thermometers are a simple and inexpensive method to record temperatures. They can be left in a cold room or supermarket refrigerator to indicate whether the maximum temperature has been exceeded at some point.Reversible temperature indicators

There are also temperature labels that display the current numerical value at all times. This way, operators can check values at a glance, which speeds up the detection of a potential problem and the decision making if safety levels in the food production processes have been exceeded.

In a few words, a temperature recorder is indispensable in the food industry. Thanks to adhesive thermometers, it is possible to keep cold temperatures under control easily and affordably and to ensure that the food is kept at appropriate preservation values. Therefore, a temperature recorder, like an adhesive label, is an excellent ally in the food industry.

Cold chain Best seller

LCD reversible adhesive temperature indicator. This label changes colour on the basis of the temperature.

Reversible temperature indicator for the...42,95 €Irreversible-type temperature indicator. These temperature labels are adhesive and can be stuck on any surface or product. They change to permanent colour when reaching the marked temperature.

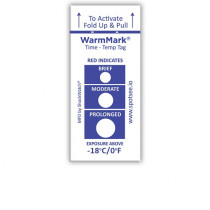

1-temperature irreversible thermometer...25,61 €Irreversible time and temperature indicator by color change. This adhesive label alerts you to inappropriate temperature exposure by progressively changing the color of the control points. Each point is calibrated for a specific period of time, thus allowing control of the exposure time at that temperature.

WarmMark Time and Temperature (pack 100...227,50 €The FREEZESAFE temperature drop indicator is an adhesive label that, by means of a color change, alerts us that the temperature has dropped below a critical value. The color change is permanent and irreversible, so it acts as a control indicator, recording the event. It is supplied in packs of 100 units.

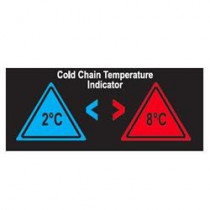

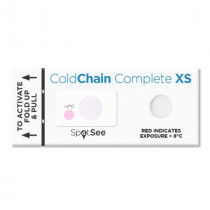

FREEZESAFE temperature drop indicator...184,17 €Coldchain complete XS is a temperature label for cold chain control. This indicator is irreversible and alerts us by means of a color change if a product has been exposed outside the required temperature range, both above and below it. It is supplied in packs of 100 units.

Coldchain Complete XS cold chain...307,00 €

The technical standard of the cold chain

Information on the cold chain can be found in Regulation (EC) No 852/2004 of the European Parliament and of the Council of 29 April 2004 on the hygiene of foodstuffs. This regulation is designed to establish general rules for the hygiene of products and to guarantee their good condition. In this area is where we find the food cold chain.The standard indicates that food cannot be stored at ambient temperature (between 15 and 30 °C). The reason behind this is simple. In this temperature range, microbes present in food will act at a higher speed, which can cause different food-borne diseases and the modification of the organoleptic characteristics of the product.

How long does it take to break the cold chain?

The chain will break when the food loses the temperature indicated for its preservation. In this sense, for refrigerated products, the temperature should not exceed 5 °C. For frozen products, the temperature should not be above −18 °C. We must highlight that the temperature we are dealing with here is that of the food and not of the cold room.

Sometimes, measuring temperature wrong can lead to error, as the temperature in some areas of the chamber can be incorrect due to the location of the temperature sensors. It can also register transitory variations, without this affecting the food, which keeps its temperature.

To prevent these problems, we can use temperature labels, as they are stuck directly onto the product or pallet, ensuring that their measurements are real.Also worth considering is the fact that, once the chain is broken, it cannot be fixed. For example, if a product is refrozen, ice crystals will form inside the food. These crystals can break down the muscle fibres in the meat and cause it to lose its characteristics.

The importance of cold chain control

Controlling the cold chain is essential. To ensure that it does not break, using temperature control labels is quite useful. These labels react by changing colour when a specific temperature is exceeded. This way, you can see if the chain has been broken at a glance and act accordingly. They are ideal for storage and, most of all, to guarantee an unbroken cold chain during transport.The use of cold chain thermometers helps us check the chain’s proper functioning. However, the only way to guarantee this is by using irreversible temperature indicators, which monitor the process from start to finish. Anyway, without a good understanding of the cold chain and its technical standard, we cannot act in an informed manner and take appropriate action. This is the only way to avoid breaking the cold chain and putting food at risk.