No products

Prices do not include tax.

FOOD CANS

Unassisted temperature control inside a melting oven during manufacture of metal packaging: check components welds.

Purpose: One of the most important manufacturers of metal packaging in Spain needed a low-cost and reliable method to control the temperature during the manufacturing process of their cans. It was necessary a completely unassisted control since the production line had to go through a melting furnace, where no operator could access for temperature measurement.

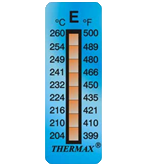

Thermosensitive product used: THERMAX 8 Labels Range E (204-260ºC). If you want to access to the online website sales, click onto the left upper "shopping basket button ".

Work done: The manufacturing line containing the tin can components goes through a flaming oven, at a determined step of the manufacture. For a few seconds, the previously welded parts of the tin can have to be cured into the oven to ensure the proper sealing and future tightness of the can. In this heating area, the temperature increases gradually up to reaching the 250°C. Determined batches are submitted to temperature control in order to certify that the appropriate temperature is maintained in this primary stage of manufacture. It is also very important to be sure that the surface of the food can has reached the proper temperature, so, the use of a label directly stuck onto the tin can ensures we are obtaining the correct reading.

Work done: The manufacturing line containing the tin can components goes through a flaming oven, at a determined step of the manufacture. For a few seconds, the previously welded parts of the tin can have to be cured into the oven to ensure the proper sealing and future tightness of the can. In this heating area, the temperature increases gradually up to reaching the 250°C. Determined batches are submitted to temperature control in order to certify that the appropriate temperature is maintained in this primary stage of manufacture. It is also very important to be sure that the surface of the food can has reached the proper temperature, so, the use of a label directly stuck onto the tin can ensures we are obtaining the correct reading.

This sensor was implemented in this application more than 15 years ago and is still used today.