No products

Prices do not include tax.

Temperature control in the manufacture of solar panels

The manufacture of solar panels has several stages. Obviously, all of them are important, but there is a specific stage that necessarily requires an adequate thermal control. This thermal monitoring must be carried out during the melting of the polyester/EVA films that will seal the assembly and protect it from the adverse weather conditions (degree of humidity, precipitation). The purified silicon crystals will capture the sunlight in order to generate electrical power.

The manufacture of solar panels with good thermal control using self-adhesive heat-sensitive labels will deliver a product with the highest performance and maximum quality.

Temperature sensors in the manufacture of solar panels

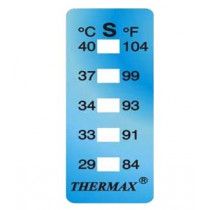

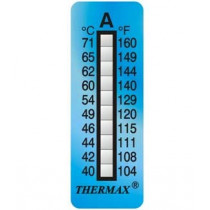

Irreversible-type temperature indicator. These temperature labels are adhesive and can be stuck on any surface or product. They change to permanent colour when reaching the marked temperature.

1-temperature irreversible thermometer...25,61 €Irreversible temperature indicator with 5 indicating points. Supplied in packets with 10 units.

5-level irreversible thermometer (pack 10...12,99 €Irreversible thermometer with de 10 temperature points.. Supplied in packets with 10 units.

10-level irreversible thermometer (pack 10...18,27 €

Critical temperature in the manufacture of solar panels: 132 °C

During the manufacture of solar panels, the ideal temperature to be reached in the polyester and glass melting stage is 132 °C. It has been proven that this temperature enables the perfect union between both components and ensures the perfect watertightness of the assembly. Watertightness is crucial for the panel to be 100% effective when it is put into service.

Advantages of using temperature labels in the manufacture of solar panels

- In the manufacture of photovoltaic solar panels, self-adhesive indicators allow the direct and unassisted control on the surface at issue. These indicators are placed at the beginning of the process. When it has finished, they allow us to check it the panel was subjected to a suitable temperature. Since they are irreversible indicators, they permanently change colour.

- The single-dot temperature label specifically allows it to be placed in small areas, as it does not require much space.

- It does not need batteries. Therefore, this indicator does not interfere with electrical circuits or enclosures which the panels go through during their manufacture.

- Cost-effective solution. Since daily checks are needed to secure the manufacturing process of photovoltaic modules, self-adhesive thermal labels are a low-cost solution that is easy to implement. These temperature sensors can be supplied in rolls of 3000 units, making them easy to handle and allowing an even lower price without performance loss.

- They are somewhat flexible so they can adhere to curved surfaces.

- Given their nature, they can be attached to quality check reports at the end of the process.